Liaoning Xinda Talc Group Co., LTD. - Li Hongpeng

In the papermaking industry, paper whiteness is one of the important indicators for measuring paper quality, which directly affects the appearance, printing effect and application fields of the paper. Talcum powder, as a commonly used papermaking filler, plays a significant role in improving the performance of paper due to its unique physical and chemical properties, with its influence on the whiteness of paper being particularly crucial. An in-depth study of the influence of talcum powder on the whiteness of paper and its mechanism of action is of great theoretical and practical significance for optimizing the papermaking process and improving the quality of paper.

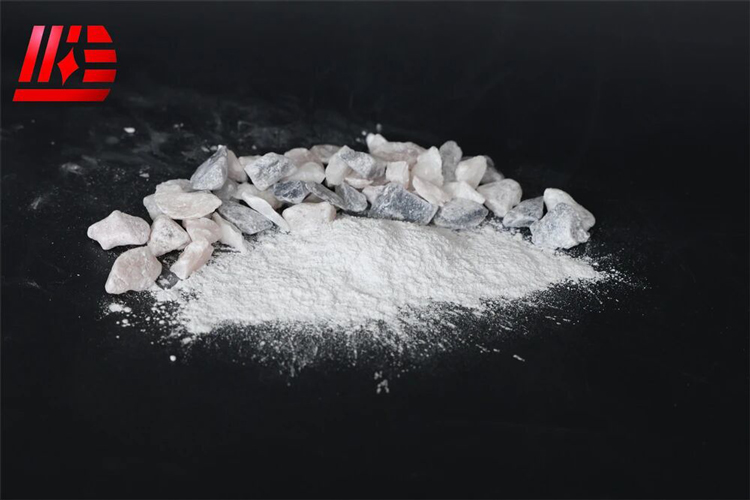

The characteristics of talcum powder: The main component of talcum powder is hydrated magnesium silicate (Mg₃(Si₄O₁₀)(OH)₂), and it has the following properties:

1. High whiteness: Natural talcum powder itself has a relatively high whiteness, usually above 90%, which lays a good foundation for it to improve the whiteness of paper.

2. Layered structure: Talcum powder has a typical layered silicate structure with weak interlayer bonding force, making it easy to peel off into thin sheets. This structure endows it with excellent dispersibility and covering property.

3. Chemical stability: Talcum powder has stable chemical properties and does not undergo adverse reactions with other chemical agents in the paper production process, thus maintaining stable performance in the paper.

4. Low oil absorption: It has a relatively low oil absorption rate and will not absorb too much ink on the paper surface, which is conducive to improving the printing effect and also reduces the adverse impact on the whiteness of the paper.

The influence of talcum powder on the whiteness of paper:

The influence of talcum powder addition amount on the whiteness of paper

Within a certain range, as the amount of talcum powder added increases, the whiteness of the paper shows an upward trend. When the addition amount of talcum powder is relatively small, its dispersion in the pulp is not uniform enough, and the effect on improving the whiteness of the paper is not obvious. However, as the addition amount increases, more talcum powder particles can fill the gaps between the fibers, reducing the light scattering loss between the fibers. At the same time, the high whiteness of talcum powder itself can be better demonstrated, thereby gradually improving the whiteness of the paper. However, when the addition amount of talcum powder exceeds a certain value, the upward trend of the paper's whiteness will gradually slow down, and even a decline may occur. This is because excessive talcum powder can lead to a decrease in its dispersibility in the pulp and make it prone to form aggregates. These aggregates not only affect the uniformity of the paper, but also increase the reflection and scattering loss of light, causing problems such as spots and flaws on the paper surface, and further leading to a decrease in the whiteness of the paper. In addition, excessive addition of talcum powder will also increase the cost of papermaking and reduce the tensile strength, tear resistance, and bursting strength of the paper.

2. The influence of talcum powder particle size on paper whiteness

The particle size of talcum powder also has a significant impact on the whiteness of paper. Generally speaking, within a certain range, the smaller the particle size of talcum powder, the larger its specific surface area, the better its dispersibility, the stronger its binding ability with fibers, and the more significant its effect on improving the whiteness of paper. Talcum powder with small particle size can fill the tiny gaps between fibers more evenly, effectively reducing the loss of light transmission and increasing the number of light reflections, making the surface of the paper whiter. In addition, talcum powder with small particle sizes can also improve the smoothness of paper, reduce the roughness of the paper surface, and further enhance the whiteness and gloss of the paper. However, when the particle size of talcum powder is too small, some problems may also arise. On the one hand, overly small particle sizes will increase the cost and difficulty of preparing talcum powder; On the other hand, the dispersion of ultrafine talcum powder in pulp is difficult to control and it is prone to agglomeration, which will instead have an adverse effect on the whiteness of the paper. Therefore, in practical applications, it is necessary to select talcum powder with an appropriate particle size based on the specific requirements of the paper and the production process.

3. The influence of using it in combination with other fillers on the whiteness of paper

In the papermaking process, talcum powder is often used in combination with other fillers (such as calcium carbonate, kaolin, etc.) to achieve better paper performance. Different fillers have a synergistic effect, which can improve the whiteness of paper while enhancing other physical and chemical properties of the paper. For instance, when talcum powder is used in combination with calcium carbonate, calcium carbonate, which has a high whiteness and covering power, can work together with talcum powder to further enhance the whiteness of the paper. Meanwhile, calcium carbonate can also improve the air permeability and printability of paper, while talcum powder can enhance the smoothness and softness of paper. The combination of the two can produce paper with better performance. For instance, when talcum powder is used in combination with kaolin, kaolin has excellent adsorption and dispersion properties, which can help talcum powder be better dispersed in the pulp, reduce the occurrence of agglomeration, and thereby improve the uniformity and whiteness of the paper. In addition, kaolin can enhance the strength and gloss of paper. When combined with talcum powder, it can meet the requirements of different paper products. However, when choosing fillers to be used in combination with talcum powder, the characteristics, proportions and compatibility among various fillers need to be taken into consideration. The addition ratio of different fillers will directly affect the changing trend of paper whiteness. Therefore, a large number of experimental studies are needed to determine the best filler combination scheme to achieve the best paper whiteness and comprehensive performance.

The mechanism by which talcum powder affects the whiteness of paper

The influence of talcum powder on the whiteness of paper due to light scattering

It is mainly achieved through the effect of light scattering. The whiteness of paper essentially reflects its ability to reflect visible light. When light strikes the surface of paper, part of the light is reflected by the surface of the paper, while the rest enters the interior of the paper, interacts with the fiber and filler particles, and is then reflected or transmitted out. Talcum powder has a relatively high refractive index (between 1.54 and 1.59), compared with the refractive index of fibers: There are certain differences in cotton 1.581-1.586, wool 1.542-1.550, silk 1.535-1.556, polyester 1.640-1.650, nylon 6 1.530-1.535, acrylic 1.510-1.515, viscose fiber 1.518-1.522. When light enters the interior of the paper, light scattering occurs at the interface between the talcum powder particles and the fibers. The presence of talcum powder particles increases the number of reflections of light within the paper, reduces the transmission loss of light, and thus enables more light to be reflected back to the surface of the paper, thereby enhancing the whiteness of the paper. In addition, the layered structure of talcum powder also helps to improve the light scattering effect. The layered structure enables talcum powder particles to form more interfaces in the paper, increasing the opportunities for light scattering and further enhancing the light scattering effect, thereby improving the whiteness of the paper.

2. Covering effect

Talcum powder has a good covering effect and can cover impurities and pigments in paper, thereby enhancing the whiteness of the paper. During the paper production process, the pulp may contain some impurities such as lignin and resin. These impurities can cause the paper to show a certain color and reduce its whiteness. Talcum powder can fill the gaps between fibers, cover the surface of impurities and pigments, and prevent their color from showing. Meanwhile, the high whiteness of talcum powder itself can also play a certain role in harmonizing the color of the paper, making the surface of the paper whiter. In addition, the layered structure of talcum powder can also form a barrier, reducing the absorption and reflection of light by impurities and pigments, and further enhancing the whiteness of the paper.

3. Improve the smoothness of paper structure

Stone powder can also enhance the whiteness of paper by improving its structure. The structure of paper includes the arrangement of fibers, the size and distribution of voids, etc. The addition of talcum powder can fill the gaps between fibers, making the structure of the paper more compact and reducing the scattering and transmission loss of light within the paper. Meanwhile, talcum powder can also improve the smoothness of paper and reduce the roughness of its surface. The smooth surface of the paper can make the light reflect more evenly, reducing the diffuse reflection caused by the rough surface, thereby improving the whiteness and gloss of the paper. In addition, the combination of talcum powder and fibers can enhance the strength of paper, reduce the damage of paper during production and use, and ensure the appearance quality and whiteness stability of paper.