Liaoning Xinda Talc Group Co., LTD. - Deng Xianghui

Talcum powder has high thermal stability and can effectively absorb and diffuse heat in plastics, thereby reducing the probability of deformation and melting of plastic products in high-temperature environments. This property enables plastics with talcum powder added to maintain their structural integrity at higher temperatures.

The flaky structure of talcum powder is neatly arranged in the polymer, forming a barrier structure. This reinforcing mechanism not only enhances rigidity but also reduces creep (i.e., the tendency of plastics to slowly deform under load). Therefore, plastics such as polypropylene filled with talcum powder exhibit better dimensional stability and heat resistance under high-temperature conditions. These factors work together to make talcum powder an effective filler for improving the heat resistance of plastics.

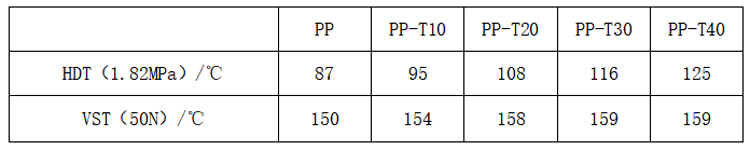

The Heat Deflection Temperature (HDT) refers to the temperature at which a plastic material undergoes a specified deformation under a particular load and heating rate. This indicator is mainly used to evaluate the short-term heat resistance of materials at high temperatures.

HDT is widely used in the performance evaluation of plastics, composite materials and polymer materials, and it is an important indicator for measuring the ability of materials to resist thermal deformation under specific loads.

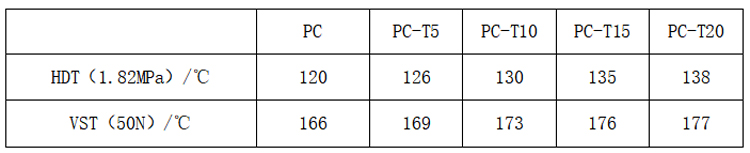

Vicat softening temperature (VST for short) refers to the temperature at which a standard indenter (with a cross-sectional area of 1m ²) is pressed into a thermoplastic sample to a depth of 1mm under a certain load and constant heating conditions. This temperature reflects the softening characteristics of the material under heating conditions and is one of the important indicators for evaluating the heat resistance of plastics. Vicat softening point is widely used in the quality control of polymer materials such as engineering plastics and general-purpose plastics, as well as in the thermal performance appraisal of new varieties. However, it should be noted that it does not directly represent the upper limit of the actual service temperature of the material.

Table 1 shows the heat distortion temperature and Vicat softening point of PP filled with talcum powder

Table 2 Heat distortion temperature and Vicat softening point of PC filled with talcum powder

Studies show that talcum powder-reinforced plastics can significantly increase their heat distortion temperature by 20-30°C, thereby extending the usability of plastics in high-temperature environments. If safety factors are taken into account, the maximum temperature for short-term use should be maintained at about 10℃ lower than the heat distortion temperature to ensure that the material does not deform due to temperature.