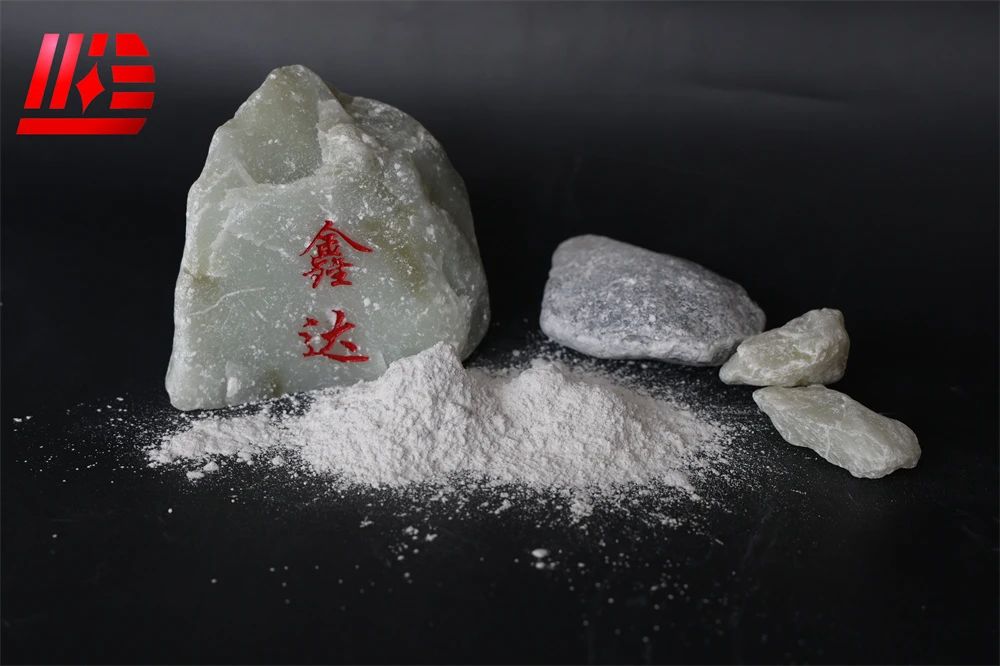

Liaoning Xinda Talc Group Co., Ltd. - Jia Weidong

The so-called beneficiation is the process of separating useful minerals from useless minerals. As a small mineral, the beneficiation of talc has not been given much attention. With the subdivision of talc powder application fields and more functional applications, talc beneficiation has higher economic value, and the development of technology and materials also provides technical basis for talc beneficiation.

The condition for separating useful and useless minerals is that there are significant property differences between minerals, which is called "washability" in mineral processing. The greater the difference, the greater the feasibility of mineral processing. As the talc ore vein in southern Liaoning, the main surrounding rock is magnesite. The more magnesite is removed from the talc ore, the higher the grade of talc ore. However, in mineral processing, the grade of useful minerals and the recovery rate of useful minerals are two important indicators that need to be balanced economically and technically. The beneficiation method is also influenced by technological, economic, and industrial policies.

Below is a brief introduction to the commonly used beneficiation methods in talc mines:

Graded mining and beneficiation method: It refers to the use of manual or small machinery to separately mine and store talc ores of different grades during the mining process, based on detection or other methods. This method is the most economical and widely used in open-pit mines, but it requires high accuracy of pre mining survey data and the experience of on-site personnel.

Screening and grading mineral processing method: The hardness difference between talc and magnesite is significant, reflecting their fragility differences. During blasting or crushing processes, magnesite is better able to maintain a certain degree of block size than talc. Therefore, various mines will use screening methods to grade talc. Generally, the grade of talc in the undersized material is higher than that in the undersized material. This method is simple, requires less investment, and has high efficiency, but the mineral processing accuracy is not sufficient. Before using this method, it is necessary to test the grade of talc ore at each particle size level in order to determine the appropriate screen size.

Manual selection and beneficiation method: Manual selection is usually divided into two categories: one is to extract obvious magnesite from talc to improve its grade, and the other is to directly select high-grade talc as concentrate. The basis for manual picking is generally color, luster, and hand feel. By distinguishing between two minerals based on these characteristics, skilled pickers need a long time of training to achieve proficiency. At the same time, picking requires high particle size requirements, and as the particle size of the ore decreases, the picking efficiency greatly decreases. For particles with a particle size less than 7mm, manual picking becomes more difficult.

Hydraulic friction beneficiation method: There is a significant difference in the surface friction coefficient between magnesite and talc, especially in the case of water wetted surfaces. Many experienced pickers understand the difference between talc and magnesite in this way. When sliding on a smooth iron plate after washing with water, magnesite and talc have a completely different sliding sensation. This difference is used to make the current drum water selection machine. This method has high mineral processing accuracy, low investment, and is easy to operate, but its efficiency is slightly lower and is greatly affected by the particle size of the ore and the cold winter weather.

Near infrared light beneficiation method: a method of beneficiation using the difference in reflection intensity of near-infrared light between talc and magnesite. At present, the development of computer and electronic control technology has greatly shortened the feedback time from recognition to injection, ensuring that what you see is what you get. According to the grade of the raw ore, forward beneficiation by spraying talc ore or reverse beneficiation by spraying magnesite ore can be used. This technology has high mineral processing accuracy and requires less manual intervention, but it has high requirements for the quality of operators, the width of ore particles, and the degree of water washing.

X-ray transmission beneficiation method: Recently, some companies have used X-ray beneficiation machines from non-ferrous metal mines for talc beneficiation, which utilizes the different X-ray transmission blocking abilities of talc and magnesite for beneficiation. This method does not require high water washing requirements, but in practice, the difference in transmission between the two is not significant, and auxiliary technology is needed to complete the beneficiation operation together.

Electrostatic beneficiation method: In this method, magnesite and talc are charged differently in a high-voltage electrostatic field or frictional electrification, and then separated by the principle of opposite polarity attraction. This method has high accuracy, but requires high particle size. Generally, only particles below 0.2mm can utilize static electricity and overcome the influence of gravity. This method is widely used in zircon sand and ilmenite, and has only been experimentally tested in talc beneficiation.

Floating beneficiation method: By utilizing the different surface properties of magnesite and talc, chemical agents are used to enlarge the surface differences by treating impurities and surfaces, thereby changing the adsorption capacity of bubbles and achieving selective carrying of talc or magnesite by floating bubbles. The flotation method belongs to the universal beneficiation method, which can achieve beneficiation of all minerals through reagent adjustment. However, it involves chemical reagents and wastewater, and is generally difficult to pass in environmental impact assessments.

AI intelligent beneficiation method: Under visible light irradiation, the ore is photographed, and the differences between talc ore and magnesite ore are manually confirmed in the photos, which are repeatedly repeated for AI to learn recognition. Generally, multiple methods such as light selection, color selection, and even X-ray transmission beneficiation are integrated and utilized for multidimensional recognition to increase accuracy. The selection accuracy of this technology depends on the recognition ability of the integrated mineral processing method and equipment, as well as the number of samples. Artificial intelligence, similar to cultivating mechanized manual picking.

Overall, in talc beneficiation, monomer dissociation degree, particle size suitability, and property differences are the basis of beneficiation. At the same time, equipping with high recognition and high feedback equipment can achieve relatively efficient high-grade talc beneficiation.