Liaoning Xinda Talc Group Co., Ltd. - Zheng Yi

Summary:

Talc powder, as an important industrial mineral filler and functional material, has unique physical and chemical properties rooted in its microscopic crystal structure. This article aims to explore in depth the formation mechanism (genesis) of the crystal structure of talc powder, analyze in detail its 2:1 type octahedral layered structure characteristics composed of silicon oxygen tetrahedral layers and magnesium oxygen octahedral layers, and systematically explain how this structure directly determines its key properties such as hydrophobicity, lubricity, adsorption, chemical inertness, and sheet-like morphology, ultimately related to its wide applications in many fields such as polymers, coatings, cosmetics, pharmaceuticals, and ceramics.

1、 Formation mechanism of crystal structure of talc powder

The chemical molecular formula of talc powder is Mg ∝ [Si ₄ O ₁₀] (OH) ₂, which is a layered silicate mineral rich in water and magnesium. The formation of its crystal structure is not achieved overnight, but has undergone a long geological evolution process, essentially a product of hydrothermal alteration and regional metamorphism.

The formation process can be summarized as the following key stages:

1. The original rock provides the material basis: magnesium rich ultrabasic rocks (such as peridotite and serpentinite) or dolomitic carbonate rocks are the main parent rocks for the formation of talc. These rocks provide the necessary sources of magnesium (Mg) and silicon (Si) elements for the formation of talc.

2. Intervention of hydrothermal fluids: In the deep crust, high-temperature and high-pressure hydrothermal fluids (rich in silica and water) migrate along rock fractures. These fluids undergo sufficient chemical reactions with the surrounding magnesium rich protoliths.

3. Complex metamorphism and alteration reactions: Complex solid-liquid chemical reactions occur under appropriate temperature (about 400-500 ° C) and pressure conditions. A typical formation pathway is the alteration of serpentinite:

Serpentine alteration:

4MgSiO(OH)₄+SiO₂→3MgSiO10(OH)₂+6HO

(Serpentine)+(Silicon Dioxide) → (Talc)+(Water)

Dolomite alteration:

3CaMg(CO₃)₂+4SiO₂+H2O→Mg3Si4O10(OH)₂+3CaCO₃+3CO₂

(Dolomite)+(Silicon Dioxide)+(Water) → (Talc)+(Calcite)+(Carbon Dioxide)

4. Directional growth of crystal structure: In the above reaction process, magnesium ions, silicate ions, and hydroxide ions in the solution begin to arrange and crystallize in an orderly manner according to the principle of lowest energy and most stability under the action of chemical driving force. They first form basic structural units, then further stack them, and finally form a complete layered crystal structure of talc. This process typically occurs on geological timescales and lasts for millions of years.

Therefore, the crystal structure of talc powder is the final result of the recombination and highly ordered arrangement of elements under specific physical and chemical conditions within the Earth's interior.

2、 Crystal structure characteristics of talc powder

The crystal structure of talc powder belongs to the monoclinic system, and its core is the classical 2:1 type octahedral layered structure (T-O-T structure). This structure can be understood from the following three levels:

1. Basic structural unit layer:

Tetrahedral Sheet-T: A hexagonal network structure consisting of two layers of [SiO ₄] ⁴⁻ tetrahedra connected by a common three vertex oxygen atoms. The top oxygen (reactive oxygen species) of each tetrahedron faces towards the inner side of the layer.

Octahedral Sheet-O: sandwiched between two silicon oxygen tetrahedral sheets is an octahedral sheet derived from brucite. Magnesium (Mg ² ⁺) cations are filled in the octahedral voids, surrounded by top oxygen and hydroxyl groups (OH ⁻) from the upper and lower layers of silicon oxygen tetrahedra. Due to the fact that all octahedral voids are occupied by magnesium ions, it is called a "three octahedral" structure.

2. Stacking and bonding of structural layers:

A silicon oxygen tetrahedral sheet, a magnesium oxygen octahedral sheet, and another silicon oxygen tetrahedral sheet are strongly covalently bonded through a shared oxygen atom, forming a robust, electrically neutral structural unit layer. The various structural unit layers are stacked together through weak van der Waals forces and intermolecular forces. The characteristic of "strong bonds within layers and weak bonds between layers" is the physical basis for all the properties of talc.

3. Chemical properties of the surface:

The surface of the structural unit layer (i.e. the basal plane of the silicon oxygen tetrahedral sheet) is composed of inert silicon oxygen bonds (Si-O-Si) without exposed hydroxyl or ionic bonds, which gives its surface a natural hydrophobic and oleophilic property.

3、 Core properties and functions determined by crystal structure

The unique crystal structure of talc powder directly endows it with a series of outstanding properties, which are fundamental to its wide application.

1. Excellent lubricity and low wear:

Mechanism of action: The layers are only connected by weak van der Waals forces, with extremely low bond energy, and are prone to interlayer slip under external forces (shear forces). This microscopic slip is manifested macroscopically as an extremely low friction coefficient and excellent lubrication effect.

Application: As a filler used in engineering plastics such as polypropylene (PP) and nylon (PA), it can significantly improve the rigidity and heat resistance of the materials, while reducing the frictional resistance during injection molding and improving processing flowability. It is also an important component of various lubricants and anti sticking agents.

2. Good hydrophobicity and organic affinity:

Mechanism of action: Its crystal surface is an inert siloxane surface that does not contain polar hydroxyl groups, therefore it has no adsorption force for water molecules and exhibits strong hydrophobicity. On the contrary, it has good compatibility with organic polymer chains.

Application: It is widely used in cosmetics (foundation make-up, talcum powder) as a skin feeling regulator for liposuction and sweat absorption; As an anti settling filler in coatings and inks, it can enhance the water resistance and corrosion resistance of the coating film.

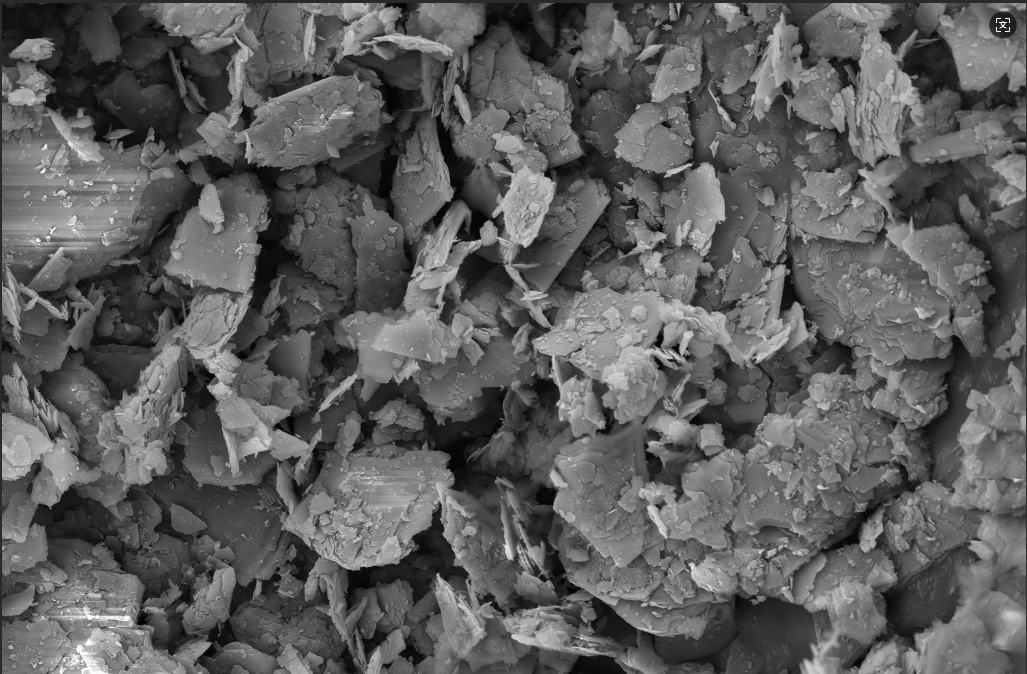

3. Flake morphology and enhancement effect:

Mechanism of action: Due to its complete lamellar cleavage (rupture along weak planes between layers), talc powder can still maintain a high aspect ratio (diameter to thickness ratio) of sheet-like particle morphology after grinding processing.

Application: In plastics, these hard sheet-like particles are dispersed in the matrix like "micron sized bricks", effectively mechanically interlocking polymer molecular chains, hindering stress transmission and deformation, thereby greatly improving the material's rigidity (modulus), creep resistance, and heat deformation temperature (HDT). In coatings, sheet-like particles are arranged in parallel to form a barrier, which can effectively block the penetration of water vapor and corrosive media.

4. Chemical inertness and thermal stability:

Mechanism of action: The internal chemical bonds of its structural unit layer are very stable, and the surface is inert, making it acid resistant, alkali resistant, and less prone to chemical reactions. The crystal structure can remain stable at around 900 ° C before undergoing dehydroxylation and decomposition.

Application: Suitable for harsh chemical environments, used as a diluent and lubricant for pharmaceutical tablets, and does not react with APIs (active pharmaceutical ingredients). Can maintain performance at high temperatures, used in fields such as ceramics and refractory materials.

5. Adsorption and covering power:

Mechanism of action: Although the surface is hydrophobic, its sheet-like structure and large specific surface area give it physical adsorption ability for oils, impurities, etc. It also provides a certain degree of coverage for light scattering and reflection (although not as good as titanium dioxide).

Application: Used as a functional filler in the coatings and paper industries, providing a certain degree of dry coverage while reducing costs. Used in personal care products to absorb excess skin oil.

4、 Conclusion and Prospect

The value of talcum powder is not just "a cheap white powder", its extraordinary multifunctional properties are deeply rooted in its unique layered crystal structure formed under geological processes. From the clever bonding of silicon oxygen tetrahedra and magnesium oxygen octahedra at the atomic scale, to the sheet-like particle morphology at the microscopic scale, and to the macroscopic performance of lubrication, hydrophobicity, reinforcement, stability, etc., a complete performance system from microscopic to macroscopic is formed.

A profound understanding of the crystal structure of talc powder is the foundation for optimizing its processing technology (such as fine grinding, surface modification to improve the aspect ratio or compatibility) and exploring new application areas. In the future, with the development of nanotechnology, the preparation of nanoscale talc layers (nano talc) by exfoliation is expected to demonstrate even more amazing potential in polymer nanocomposites, high-performance barrier films, and other fields, further highlighting the core value of this ancient mineral in modern industry.