Liaoning Xinda Talc Group Co., Ltd. - Cao Xinyu

Abstract:

This study focuses on the resource utilization of talc solid waste and provides a detailed introduction to the talc solid waste light selection and flotation linked mineral processing technology developed by Liaoning Xinda Talc Group Co., Ltd. This technology integrates X-ray diffraction analysis, intelligent ore sorting machine pre selection, as well as crushing and screening, grinding, and flotation processes, achieving efficient recovery of talc solid waste. This technology has improved resource utilization, reduced production costs, minimized environmental pollution, and provided a new approach for the comprehensive utilization of talc solid waste, which is of great significance for promoting the sustainable development of the talc industry.

Keywords: talc solid waste; Linkage between light selection and flotation; Mineral processing; resource utilization

1. Introduction

China has abundant talc resources, but high-quality talc resources are becoming increasingly scarce. A large amount of solid waste is generated during the mining and processing of talc, and the storage of these solid wastes causes damage to the environment and lacks effective application value. The traditional mineral processing method is not effective in treating low-grade talc solid waste, especially for parts with talc content ≤ 35%, and lacks effective recovery methods. Therefore, it is particularly urgent to develop efficient comprehensive utilization technology for talc solid waste.

2、 Background and significance of process research and development

2.1 Current situation and problems of talc resources

China's talc resources are widely distributed, but after long-term mining, high-quality talc resources are becoming increasingly scarce. During the mining and processing of talc, a large amount of talc solid waste is generated, which contains valuable minerals such as talc and magnesite. However, these solid wastes have not been effectively utilized, and their storage not only occupies a large amount of land, but also causes serious pollution to the environment.

2.2 Limitations of Traditional Mineral Processing Methods

At present, the main beneficiation methods for low-grade talc include flotation, manual selection, electrostatic beneficiation, magnetic separation, photoelectric detection, selective crushing, and screening. However, these methods have significant shortcomings when dealing with talc solid waste with a talc content of ≤ 35%. For example, the flotation agents used in flotation methods cannot naturally degrade, have poor environmental friendliness, and have unsatisfactory treatment effects on solid waste containing low levels of talc ore; The manual selection method has low efficiency and is difficult to handle large amounts of solid waste; The application scope of electrostatic beneficiation and magnetic separation methods is limited.

2.3 Significance of Developing New Processes

The development of a mineral processing technology that combines the light separation and flotation of talc solid waste has important practical significance. On the one hand, this technology can recover high-grade talc concentrate and magnesite from useless talc solid waste, improve resource utilization, and alleviate the pressure of talc resource shortage in China; On the other hand, it reduces the storage of solid waste from talc mines, reduces environmental pollution, and has good environmental benefits; In addition, by optimizing the beneficiation process and parameters, production costs have been reduced and the economic benefits of the enterprise have been improved.

3、 Process principles and equipment

3.1 Process principle

This technology combines the advantages of light selection and flotation, utilizing the differences in physical and chemical properties between talc and gangue minerals. It first undergoes preliminary separation through light selection, and then further purification is achieved through flotation. Light selection is based on the appearance characteristics or specific physical properties of minerals for initial enrichment, while flotation utilizes the differences in surface wettability of minerals for mineral separation in a gas liquid solid three-phase interface system.

3.2 Key Equipment

X-ray diffraction analyzer: used for structural analysis, main chemical composition analysis, mineral composition and relative content determination of raw ore, providing a basis for subsequent beneficiation.

Intelligent ore sorting machine: It can use artificial intelligence sorting machine or X-ray intelligent sorting machine to classify talc solid waste and obtain M46A grade magnesite and talc solid waste.

Crusher: such as roller crusher, impact crusher, etc., crushes the intelligently pre selected talc solid waste to achieve the appropriate particle size.

Vibration screening machine: including linear vibration screen, circular vibration screen, etc., screens the crushed materials to obtain the required particle size.

Vertical mixing mill: such as a vertical zirconia ball mill, grinds the screened material to obtain a talc solid waste slurry with appropriate concentration.

Flotation machine: The Dafkele (jet compressed air) flotation machine is used to flotation the solid waste slurry of talc ore to obtain talc concentrate.

4、 Process flow and operational steps

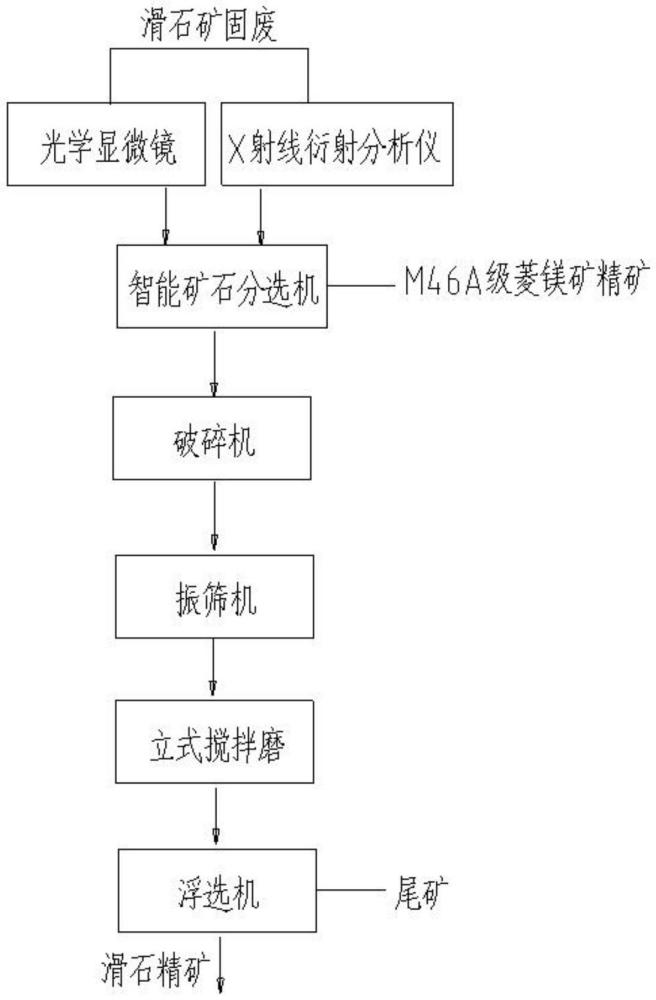

Process Flow Diagram

4.1 Mineralogy analysis of raw ore

Through experimental equipment such as optical microscopes and X-ray diffraction analyzers, detailed analysis of the raw ore is carried out to determine its structural structure, main chemical components, mineral composition, and relative content. The embedding characteristics, particle size distribution characteristics, and dissociation degree of important minerals are obtained, providing basic data for subsequent ore selection.

4.2 Intelligent Pre selection

Using an intelligent ore sorting machine to classify talc solid waste, it is classified into M46A grade magnesite and talc solid waste based on the different physical characteristics of the minerals. By continuously optimizing the sorting parameters, the pre selection effect is ensured and the subsequent beneficiation efficiency is improved.

4.3 Crushing and screening

Crush the talc solid waste after intelligent pre selection and use a suitable crusher to crush it to a 7mm sieve size. The crushed material is then sieved by a vibrating screen to ensure that the particle size meets the requirements. This step can be continuously repeated until the grade of the crushed ore stabilizes.

4.4 Grinding

Use a vertical mixing mill to grind the crushed and screened material, obtaining a solid waste slurry of 50% talc ore with a proportion of 65% under the 0.074mm sieve. During the grinding process, ensure that talc is fully dissociated from other minerals to create favorable conditions for subsequent flotation.

4.5 Flotation

Pour the ground talc solid waste slurry into the mixing tank and add 40g of sodium dodecyl sulfonate per ton of ore for slurry adjustment. The slurry after slurry adjustment enters the coarse flotation machine for talc coarse selection, obtaining talc coarse concentrate. Continue to add 20g of sodium dodecyl sulfonate per ton of ore to the flotation machine for cleaning, obtaining talc cleaning medium ore and tailings. The cleaning medium ore is returned to the coarse selection for further selection. Perform three rounds of precision flotation on the crude talc concentrate to obtain talc concentrate and selected intermediate ore. The talc concentrate is the final product, and the selected intermediate ore and the swept intermediate ore are returned to the previous flotation operation in sequence.

5、 Technological advantages and innovation points

5.1 Improve resource utilization efficiency

This technology can recover high-grade talc concentrate and magnesite from talc solid waste with talc content ≤ 35%. The talc concentrate has a whiteness of 92, acid soluble iron content ≤ 0.5%, talc purity ≥ 91.3%, and CaO content ≤ 1%; The indicators for grade A magnesite M46 are: MgO ≥ 46%, CaO ≤ 0.6%, SiO2 ≤ 0.6%. Greatly improving the resource utilization rate of talc solid waste and reducing resource waste.

5.2 Reduce production costs

By optimizing the flotation beneficiation process and parameters, energy consumption has been reduced and production costs have been lowered. At the same time, the use of degradable flotation agent sodium dodecyl sulfonate is only 50 times the amount used in shampoo, further reducing the cost of the agent.

5.3 Significant environmental benefits

This technology has achieved a comprehensive utilization rate of 65% for talc solid waste, reducing the degree of environmental pollution caused by the storage of talc solid waste. The flotation reagents used are naturally degradable, environmentally friendly, and in line with the concept of green development.

5.4 Innovation points

This technology innovatively combines light separation and flotation techniques, fully leveraging the advantages of both beneficiation methods. Light selection technology can quickly and efficiently classify solid waste of talc ore, while flotation technology further purifies talc concentrate, improving product quality. In addition, the intelligent ore separator and degradable flotation reagents used in the process also reflect the innovation and progressiveness of the process.

6、 Application prospects and prospects

6.1 Application prospects

With the increasing shortage of talc resources and the continuous improvement of environmental protection requirements, the mineral processing technology of talc solid waste light selection and flotation linkage has broad application prospects. This technology is not only suitable for the treatment of talc solid waste, but can also be widely applied to the comprehensive utilization of other similar low-grade minerals, providing new ideas and methods for the sustainable development of mineral resources.

6.2 Outlook

In the future, this technology should be further optimized to improve its stability and adaptability. Strengthen cooperation with scientific research institutions, conduct relevant basic research, deeply explore the synergistic mechanism of light selection and flotation, and provide theoretical support for technological improvement. At the same time, we will increase our research and development efforts on biodegradable flotation reagents, develop more environmentally friendly and efficient flotation reagents, and promote the comprehensive utilization of talc solid waste to a higher level.

VII. Conclusion

The integrated mineral processing technology of talc solid waste light selection and flotation is an important innovative achievement of Liaoning Xinda Talc Group Co., Ltd. in the comprehensive utilization of talc solid waste. This technology achieves efficient recovery and comprehensive utilization of talc solid waste through the organic combination of light selection and flotation, improves resource utilization, reduces production costs, and has good environmental benefits. With the continuous improvement and promotion of technology, this technology will play an important role in the talc industry and even the comprehensive utilization of mineral resources, making positive contributions to the sustainable development of mineral resources in China.

References

[1] Liaoning Xinda Group Technical Report on Resource Utilization of Talc Solid Waste [R]. Haicheng: Enterprise Technology Center, 2023

[2] U.S. Geological Survey. Mineral Commodity Summaries 2023[Talc][R]. Reston: USGS, 2023: 172-173.

[3] Li Zhiwei, Wang Zhenhua The current situation and sustainable development strategy of talc resources development in China [J]. Mineral Protection and Utilization, 2022, 42 (3): 45-51

[4] China Non metallic Mineral Industry Association White Paper on Talc Mineral Processing Technology [Z]. Beijing: Association Press, 2021: 28-30

[5] China Non metallic Mineral Industry Association 2024 Report on the Development of China's Talc Industry [R]. Beijing, 2024

[6] Liaoning Xinda Talc Group. A combined process of talc solid waste photoelectric separation flotation: CN114308356A [P]. 2022-04-12