Liaoning Xinda Talc Group - Zheng Yi

1、 The shielding effect of talc structure on corrosion prevention

Talc is a layered silicate mineral whose unique properties stem entirely from its special structure at the macroscopic to atomic scales.

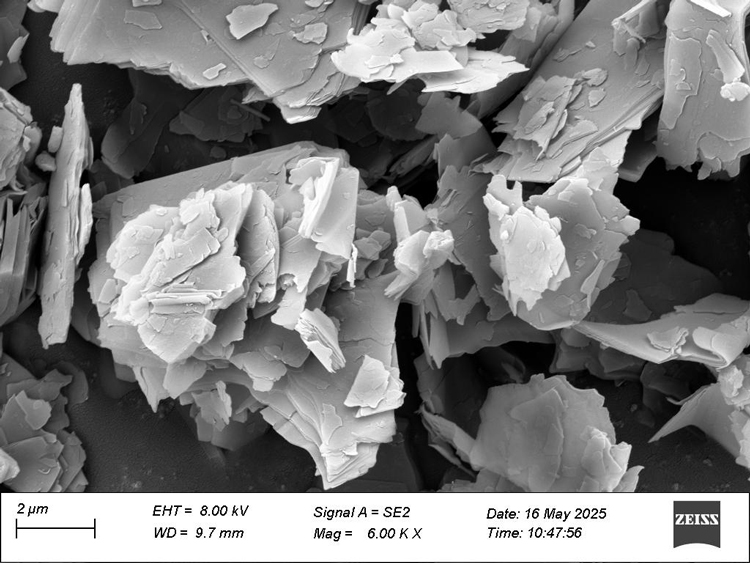

1.1 Scanning Electron Microscope (SEM) Observation:

Morphological features:

Under SEM, talc powder appears as typical flakes or scales, with clear boundaries of high-purity talc particles and visible large layered structures stacked together.

Diameter to thickness ratio measurement:

SEM images can be used to quantitatively analyze the aspect ratio of particles, which is the ratio of the diameter to thickness of sheet-like particles. High quality anti-corrosion coatings using talc powder exhibit a very high diameter to thickness ratio under SEM, with particles overlapping like thin gauze

Cleavage characteristics:

Talc has extremely complete basal cleavage. In SEM, flat and smooth step like cross-sections formed by the rupture of particles along the cleavage plane can be clearly observed. This is a direct reflection of its crystal structure on the microscopic morphology.

After the formation of the paint film, it is precisely this layered structure that requires the corrosive medium to bypass it, greatly prolonging the penetration path and delaying the time to reach the substrate, thereby reducing the occurrence of corrosion. This is the shielding effect of talc.

1.2 Atomic arrangement and crystal structure of talc

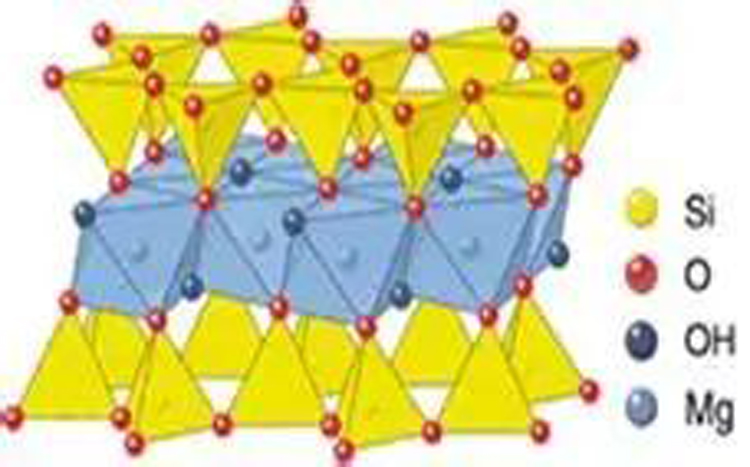

The basic structural unit of talc is an electrically neutral T-O-T sandwich layer. This name vividly describes its atomic stacking method:

Lower layer "bread slice": Tetrahedral Sheet-T is a continuous hexagonal network layer formed by [SiO ₄] ⁴⁻ tetrahedra connected by common vertices (i.e. shared oxygen atoms). Each tetrahedron has an unshared apical oxygen pointing towards the center of the layer.

Sandwich layer ": The center of the magnesium oxide octahedral Sheet-O is a trioctahedral sheet. Formed by [MgO ₄ (OH) ₂] octahedra connected by common edges. The center positions of all octahedra are occupied by divalent magnesium ions (Mg ² ⁺) ("triahedra" refers to all possible positions being occupied). The (OH) ⁻ group in the octahedral sheet is connected to the apical oxygen of the upper and lower tetrahedral sheets through a shared proton.

Upper layer "bread slice": The tetrahedral Sheet-T structure is completely symmetrical to the lower layer.

Bonding method: Within a T-O-T sandwich layer, silicon, magnesium, oxygen, and hydrogen atoms are bonded together through strong ionic and covalent bonds, forming a very robust, stable, and electrically neutral overall structural unit. The ideal thickness of this unit layer is about 0.94nm.

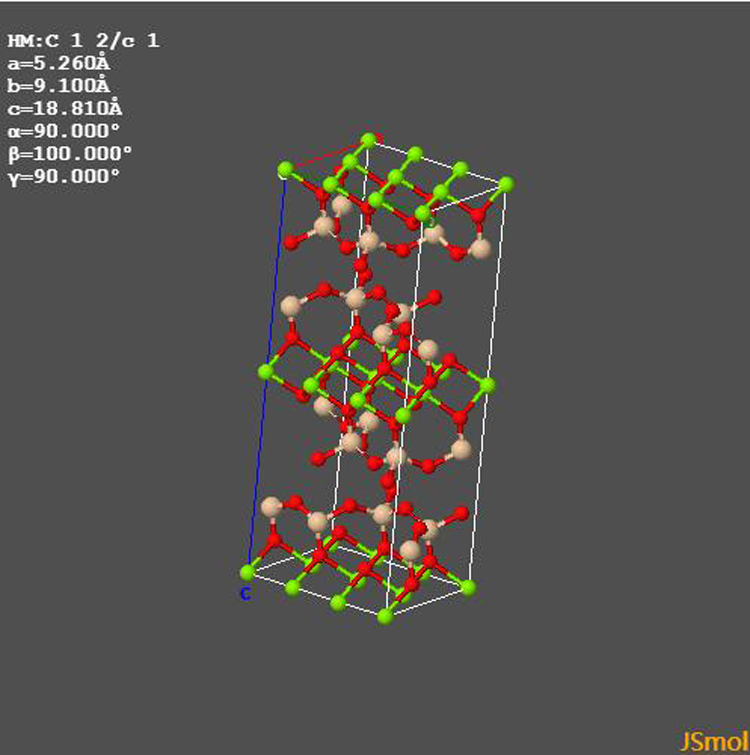

1.3 Crystal Systems and Space Groups

Crystal System: Monoclinic

Space group: * C2/c * (this is the standard symbol in the International Crystallographic Tables to represent its symmetry operation)

Cell parameters:

a≈0.527nm

b≈0.912nm

C ≈ 1.885nm (this direction is the direction of layer stacking)

β≈100°

The atomic arrangement of talc is the ultimate answer to its function. The T-O-T sandwich layer provides strength and inertness, while the van der Waals forces between the layers endow it with the characteristic of easy cleavage into flakes. This structure, predetermined at the atomic scale, makes it an ideal material for improving the shielding performance and durability of anti-corrosion coatings. Choosing talc is essentially choosing a perfect microstructure that has been verified by nature for billions of years.

2、 Interface bonding and film densification of talc

There are silanol bonds (Si OH) and magnesiol bonds (Mg OH) on the surface of the layered talc powder. These functional groups can form strong hydrogen bonding interactions with polymer resins, such as epoxy groups and hydroxyl groups in epoxy resins.

Enhanced interface bonding: Strong interface bonding means that stress can be effectively transferred from the weaker polymer matrix to the rigid talc layer, significantly improving the deformation resistance and cohesive strength of the paint film.

Reduce interface defects: Good compatibility and bonding reduce micro defects and pores between polymers and fillers, making the paint film denser and reducing the "short circuit" channels for medium penetration from the source.

3、 The positive effect of trace element composition of talc on corrosion prevention

Haicheng talc mineralization:

3MgCO₃+4SiO₂+H₂O→Mg₃[Si₄O₁₀](OH)₂+3CO₂↑

The talc mine in Haicheng, due to the fact that the ore-forming surrounding rocks, especially the near ore surrounding rocks, are almost all magnesite marble or quartz magnesite marble, and the accompanying minerals of talc in the ore are rare, through the analysis of more than 300 samples in the mining area and periphery, no calcite or other calcium rich minerals were found, and no calcite veins were formed near the deposit. Especially in the Fanma mining area where Xinda Talc Group is located, it is a typical and high-quality talc deposit formed by silicon dioxide hydrothermal metasomatism with magnesite as the bedrock. This determines that Fanma talc has excellent genes from birth.

The extremely low distribution of pyrite (FeS ₂), magnetite (Fe ∝ O ₄), or hematite (Fe ₂ O ∝) reduces the production of Fe+as a cathode in batteries, thereby reducing the occurrence of electrochemical reactions and pitting phenomena.

The formation of Haicheng ore veins is mainly due to the alteration of magnesite, with extremely low impurities of calcium carbonate, which is greatly reduced

The production of CaCO ∝+2H ⁺ → Ca ² ⁺+CO ₂ ↑+H ₂ O reaction reduces the formation of coating bubbles and pores.

4、 Research achievements of Liaoning Xinda

Liaoning Xinda has developed a universal talc powder specifically for anti-corrosion systems, which has the advantages of good flake structure and low oil absorption.

In the formula of epoxy resin, 0 # is used without adding talc powder, 1 # is added with Xinda talc powder, and 2 # is added with other talc powders.

Experimental project | 0# | 1# | 2# |

Grid experiment | 1 | 1 | 1 |

Stormer viscosity/KU | 119 | 136 | 144 |

Coating appearance | Normal | Normal | Normal |

Impact resistance/cm | 50cm | 50cm | 50cm |

Bend Test | 3 | 3 | 3 |

Adhesion/MPA | 6.0 | 7.4 | 6.2 |

Salt spray resistance/720h | No rust, no bubbles, no peeling, no cracking Corrosion average value0.9mm Adhesion:3.6 | No rust, no bubbles, no peeling, no cracking Corrosion average value0.6mm Adhesion:5.2 | No rust, no bubbles, no peeling, no cracking Corrosion average value0.7mm Adhesion:4.3 |

Acid resistance/(5% sulfuric acid 168h) | No rust, no bubbles, no peeling, no cracking | No rust, no bubbles, no peeling, no cracking | No rust, no bubbles, no peeling, no cracking |

Alkali resistance (5% NaOH 168h) | No rust, no bubbles, no peeling, no cracking | No rust, no bubbles, no peeling, no cracking | No rust, no bubbles, no peeling, no cracking |

Salt water resistance (5NaCl 168h) | No rust, no bubbles, no peeling, no cracking | No rust, no bubbles, no peeling, no cracking | No rust, no bubbles, no peeling, no cracking |

Compared with 0 # coating, the basic paint film indicators such as scratch test, impact resistance, and bending test of 1 # coating are the same as those of 0 #, and its adhesion is higher than that of 0 #, with an improvement of 20%. Due to the sheet-like or fibrous structure of talc powder, it absorbs stress during the drying process of the paint film, maintaining the dimensional stability of the paint film and helping to improve adhesion. The adhesion of coating 1 # after salt spray resistance test is higher than that of coating 0 #, indicating a significant improvement in corrosion resistance.

The scratch test, impact resistance, bending test and other paint film indicators of the 2 # coating are the same as the original formula, and the adhesion improvement is not significant. Its salt spray test can be basically the same as that of the 0 # coating.

Stormer viscosity increases, with 1 # being smaller and having lower oil absorption values. The resin adsorption capacity is also lower, which can reduce the amount of resin used while ensuring coating performance. The decrease in viscosity can reduce energy consumption during paint processing, making it difficult for powder pigments and fillers in the paint system to settle, which is beneficial for improving product storage stability; Reduce the amount of volatile diluents used in actual production and spraying to lower VOC content.