Author: Cao Xinyu

Unit: Liaoning Xinda Talc Group Co., Ltd. (Haicheng, Liaoning)

Summary:

This article focuses on the application and advantages of ultrafine talc powder with high aspect ratio in polypropylene plastics. Firstly, the sheet-like structure and bonding method of talc powder were introduced, and then the technical difficulties in the production process were analyzed. Subsequently, based on the research and development achievements of Liaoning Xinda Talc Group R&D Center, the significant effect of its 3000 mesh talc powder in protecting large scales was introduced, and the superior diameter to thickness ratio of its talc powder was demonstrated through comparative images. Finally, the practical application effects and market feedback of high aspect ratio talc powder in plastics were summarized.

Keywords: talc powder, diameter to thickness ratio, van der Waals force, atomic structure

1、 Introduction

Talc powder has been widely used as the main filler in the polypropylene plastic industry due to its high thermal stability, chemical inertness, good dispersibility, and reinforcement effect. Especially in improving the mechanical properties, heat resistance, and dimensional stability of polypropylene plastic products, it has played an important role. In the industry, a large number of experiments have been conducted on the influence of talc powder fineness (particle size) on the properties of polypropylene, but there is relatively little research on particle morphology. The R&D center of Xinda Talc Group has discovered this issue and has started researching it. Talc powder has a typical sheet-like structure at the microscopic level, but due to different powder processing techniques, the maintenance of its sheet-like structure is also not the same, and there is little research on the way and influence of describing the sheet-like structure. This article provides a preliminary directional explanation of the effect of talc powder flake structure and its influence on the mechanical properties of polypropylene plastics using a diameter to thickness ratio.

2、 Xinda Talc Powder Factory and Structure and Bonding Method of Talc Powder

1. Introduction to Xinda Talc Powder Factory

Liaoning Xinda Talc Group Co., Ltd. was established in 1995 and is an enterprise group that integrates talc mining, sorting, research and development, deep processing, and sales. Xinda Talc Group ranks among the top five talc enterprises in China and is a research and development center for talc technology in China. The group's annual production of high-end talc products accounts for 15% of the national talc market. Xinda Powder Factory was founded in 1995, with 30 years of deep cultivation and research in the powder area to solve customers' worries. The factory covers an area of 70000 square meters and mainly produces various types of talc powder, with an annual production capacity of 300000 tons and the ability to store 50000 tons of talc raw materials. It has more than 70 employees. Xinda Powder Factory has advanced production equipment, including 2 German imported flake air flow mills, 2 domestically advanced dual stage wheel air flow mills, 2 screening machines, and 6 vertical mills. The production line is fully enclosed with a pipe chain conveyor, without external pollution. A fully automatic packaging production line has been introduced to achieve functions such as bagging, measuring, counting, dust removal, coding, and high-level stacking of product packaging. The raw material feeding adopts an automatic feeding system to achieve the automation of talc raw material ratio and mixing, making the raw material ratio reliable and accurate, reducing fluctuations in product indicators, and ensuring more stable technical indicators such as whiteness and color, ensuring that product quality meets the needs of domestic and foreign customers.

With the development of modern industry, the application fields of talc powder are becoming more extensive. Talc powder plays an indispensable role in various industries such as plastics, rubber, paint, industrial ceramics, and papermaking. Its unique physical and chemical properties make it an important mineral raw material in modern industry.

2. Structure and binding mode of talc powder

Talc powder is a layered silicate mineral with a typical sheet-like structure. Each piece of talc is mainly bound by van der Waals forces, which are relatively weak, making it easy for the talc pieces to slide and separate when subjected to external forces. However, for each piece of talc, its internal atomic structure is tightly bound together through covalent and ionic bonds, possessing high strength and stability.

In the production process, achieving the goal of breaking van der Waals forces and effectively protecting the interatomic structure is a technical challenge. Excessive mechanical or high-temperature treatment may cause damage to the atomic structure inside the talc like structure, thereby affecting its performance. Therefore, how to maintain the integrity of its internal structure while ensuring the dispersibility and enhancement effect of talc powder is an important research direction in the production process of talc powder.

3、 Technical difficulties in the production process

In the production process of talc powder, in order to achieve the ideal particle size distribution and diameter to thickness ratio, a series of pulverization and grading processes are required. However, these manufacturing processes often have an impact on the sheet-like structure of talc powder.

flour milling technology

The milling process is one of the key steps in the production of talc powder. By crushing, large talc raw materials can be broken into smaller particles. However, in the powder making process, if the equipment parameters are adjusted too high, it will damage the atomic structure of talc, causing talc to appear spherical and seriously affecting the microscopic flake morphology of talc powder. If the device parameters are too low, it can effectively protect the atomic structural forces and break the annoying Waltz forces between layers, but it will seriously affect production capacity, making production uneconomical. During the milling process, improper adjustment of equipment parameters may cause damage to the atomic structure inside the talc sheet, thereby affecting its performance. Therefore, it is necessary to select appropriate grinding equipment and process parameters to ensure the grinding effect and integrity of the flake structure of talc powder.

Classification process

The grading process is the process of separating talc powder based on particle size. By grading, talc powder products with specific particle size distribution can be obtained. However, impurities may be introduced or particles may agglomerate during the grading process, which can affect the dispersibility and reinforcement effect of talc powder. Therefore, it is necessary to adopt specially designed and efficient grading equipment and process parameters to ensure the sheet-like structure and particle size distribution of talc powder.

4、 Liaoning Xinda Talc Group R&D Center and Achievements

In response to the technical difficulties in the production process of talc powder, the R&D department of Liaoning Xinda talc group has conducted a large number of research and development experiments. By continuously improving production processes and parameters, we have successfully developed a high diameter to thickness ratio 3000 mesh sliding stone powder product with excellent performance.

4.1 Liaoning Xinda Talc Research and Development Center

In response to the national innovation driven development strategy and to promote industrial upgrading and technological breakthroughs, the group approved the expansion project plan for the existing research and development center in April 2024, and construction began in May 2024. Xinda R&D Center focuses on the key technology research and achievement transformation of talc materials in the fields of plastics, coatings, papermaking, etc. The center aims to achieve "independent innovation and industrial empowerment" by integrating industry university research resources to create a technology innovation platform with international competitiveness.

The main building of the R&D center consists of three floors with a construction area of 1300 square meters. It is equipped with one innovation studio, two expert studios, three processing laboratories, four testing laboratories, and multiple functional rooms. Among them, the testing laboratory is equipped with 105 sets of advanced testing equipment, including cutting-edge analytical instruments such as Malvern particle size analyzer, which can accurately complete special tests such as talc powder particle size distribution, asbestos content analysis, and heavy metal migration detection; The processing laboratory is equipped with 18 sets of intelligent testing equipment, fully covering the research and development needs of new products in the fields of modified plastics, coatings, papermaking, etc. The center is led by technical experts in the inorganic powder, paper, plastic, and coating industries, with a team of 33 members all having bachelor's degrees or above. Their majors cover disciplines such as polymer materials engineering, inorganic non-metallic materials engineering, chemical engineering, and mineral processing.

Xinda R&D Center adheres to the concept of "innovation driven development", deeply integrates resources from universities and research institutes, and builds an open research platform. Through the dual wheel drive of technological breakthroughs and achievement transformation, we have launched multiple talc application technologies with independent intellectual property rights, serving industries such as mineral processing, environmentally friendly materials, and high-end coatings. We are gradually growing into an internationally leading talc technology research base.

4.2 Research and Development Achievements

Talc powder plays an important role in improving the mechanical properties, heat resistance, and dimensional stability of polypropylene plastic products. Talc powder has a typical sheet-like structure at the microscopic level, but due to different powder processing techniques, the maintenance of its sheet-like structure is also not the same. Maintaining a good sheet-like structure (which can be measured by the diameter thickness ratio or peeling ratio) has a significant impact on the mechanical properties of polypropylene plastics.

In the production process of talc powder, in order to achieve the ideal particle size distribution and maintain a high aspect ratio, it is necessary to select or modify grinding and grading equipment, and accurately set the grinding process parameters.

4.21 Liaoning Xinda Talc Group improves by utilizing airflow crushing technology:

1. Accurately set the particle size distribution for pre grinding as the raw material for airflow crushing.

2. The original airflow nozzle has been rearranged to reduce collisions and increase shear and abrasion forces.

3. Conduct experiments to determine the temperature and flow rate of compressed air.

4. Adopting multi-stage classifier linkage technology.

5. Add a dispersant as a stripping tablet.

After experimentation, the production of 3000 mesh sliding stone powder with a high aspect ratio has been successfully achieved, with a aspect ratio of 16-18 and an equivalent peeling ratio of 3.8-4.5

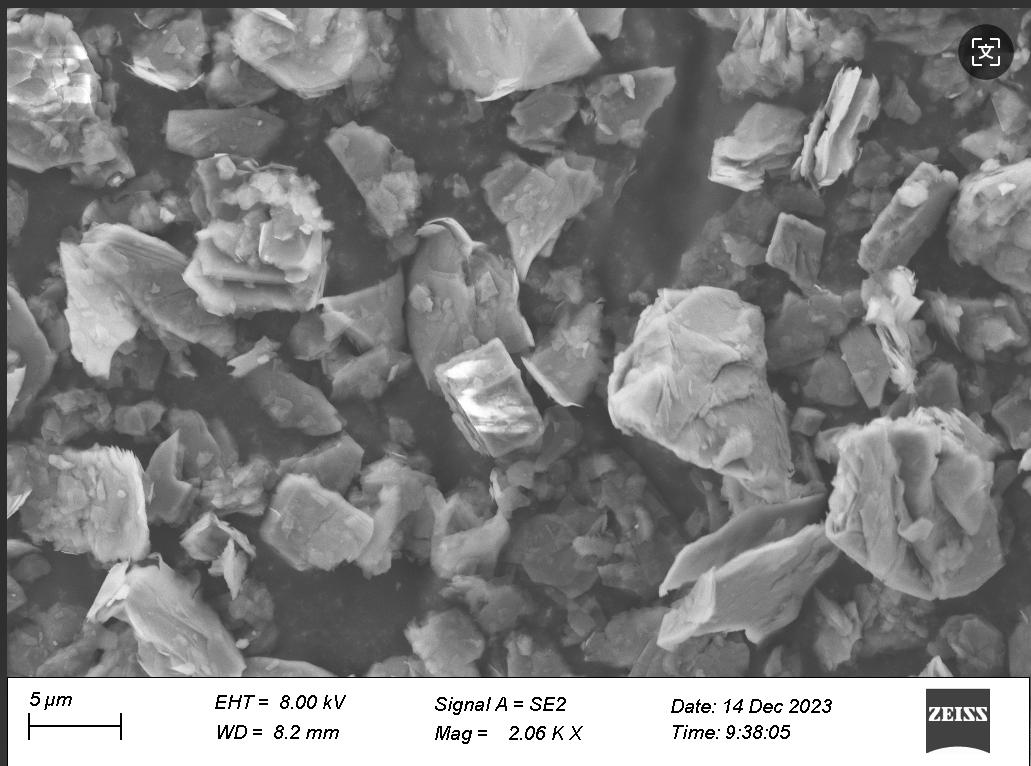

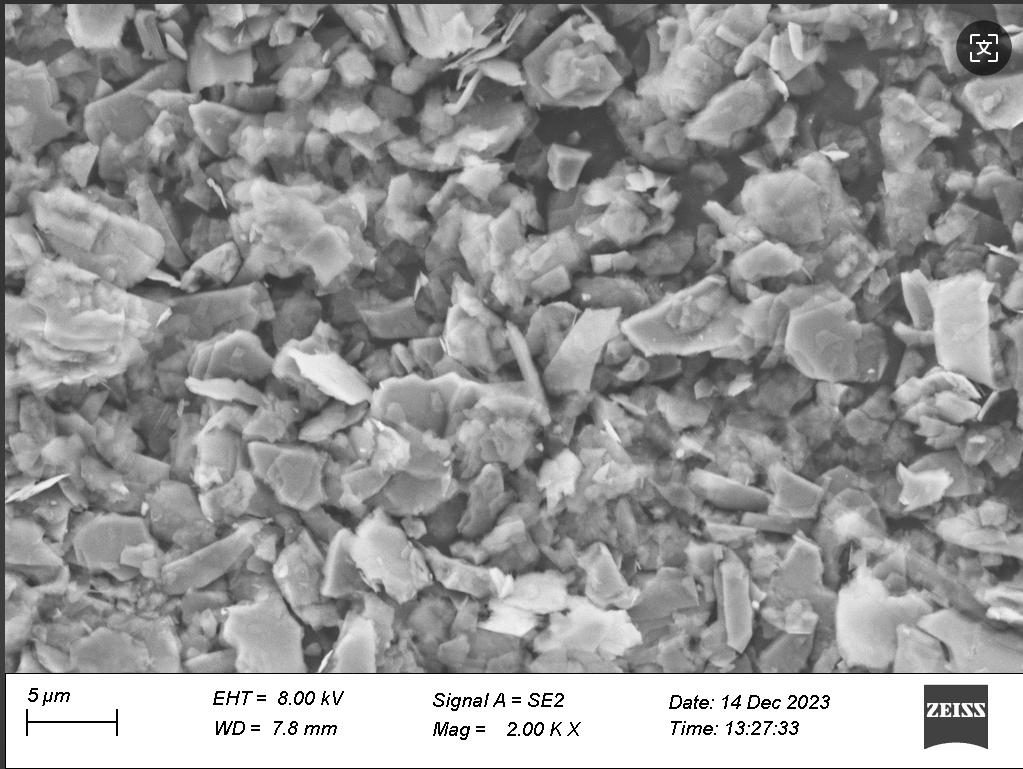

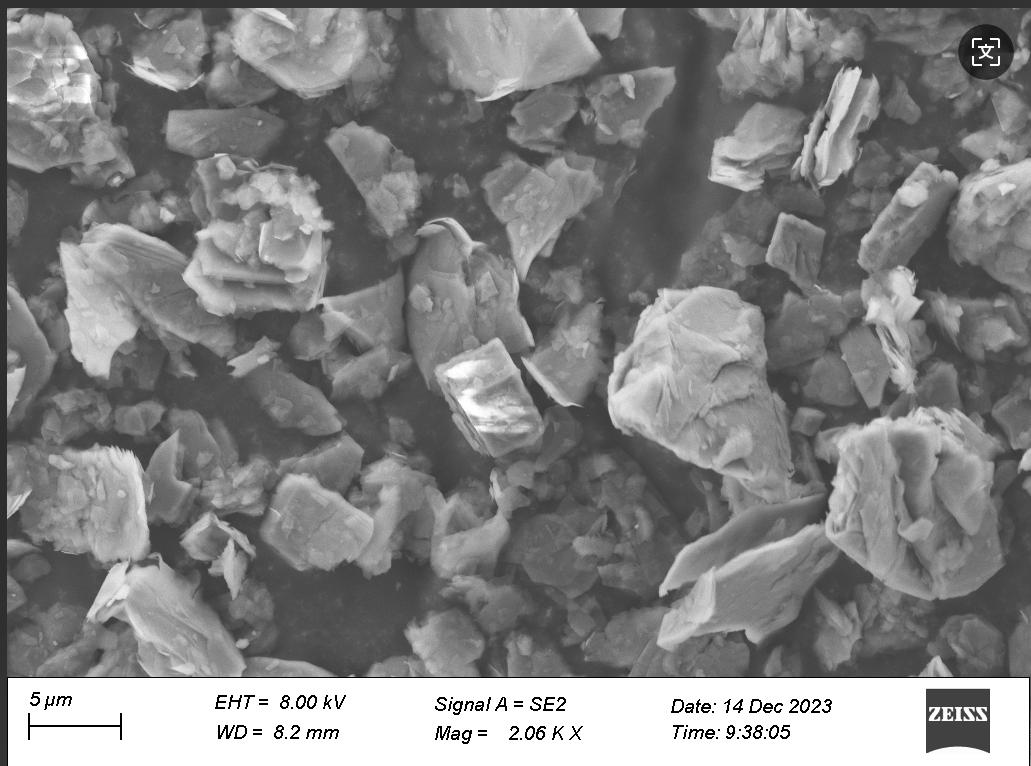

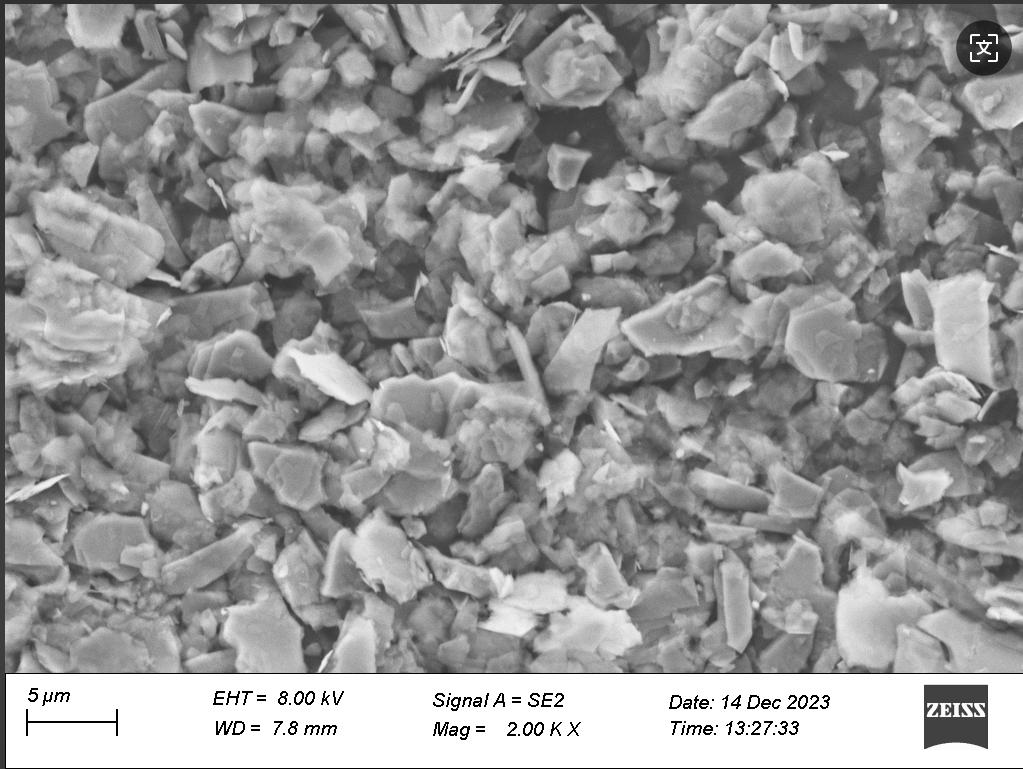

The SEM image is as follows:

Figure 1: 3000 mesh sliding stone powder produced by the original ordinary process

Figure 2: Photo of high peel ratio 3000 mesh sliding stone powder

Two types of 3000 mesh talc powders were compared for application in polypropylene plastics:

1. Laboratory data shows that the impact, tensile, and bending strength of the powder increased by 3-5% year-on-year after adding high diameter, and the increase was synchronous.

2. Laboratory data shows that the shrinkage rate of powder with a high aspect ratio decreased by 6-8% year-on-year.

By adding talc powder with a high aspect ratio, the amount of plastic additives can be reduced while ensuring the performance of plastic products.

The experimental results show that Liaoning Xinda Talc Group Co., Ltd. has developed a high diameter to thickness ratio of 3000 mesh talc powder, which exhibits excellent reinforcement effect, heat resistance, and cost reduction effect in polypropylene plastics.

4.22 Protection of Achievements

(1) The effect of protecting large scales

During the research and development process, the R&D department of Liaoning Xinda Talc Group pays special attention to protecting the large scale structure of talc sheets. By optimizing the parameters of grinding equipment, grading, and surface treatment processes, effective protection of large scales has been successfully achieved. This enables 3000 mesh talc powder to maintain its bulk density, protect the high dispersibility and reinforcement effect of ultrafine talc powder, while also possessing excellent diameter to thickness ratio and mechanical properties.

(2) Comparison image display

In order to visually demonstrate the advantages of the talc powder of Liaoning Xinda Talc Group Co., Ltd. in terms of diameter to thickness ratio, we provide the following two comparative pictures:

Figure 1: Photo of similar products in the industry under electron microscopy

(Note: This is a schematic description, and the actual image should show the morphological characteristics of talc powder produced by other manufacturers in the industry under electron microscopy.)

Figure 2: Photo of 3000 mesh talc powder produced by Liaoning Xinda Talc Group Co., Ltd

(Note: This is a schematic description, and the actual image should show the morphological characteristics of 3000 mesh talc powder produced by Liaoning Xinda Talc Group Co., Ltd. under electron microscopy.)

From the comparison pictures, it can be seen that the 3000 mesh talc powder produced by Liaoning Xinda Talc Group Co., Ltd. is significantly better than other products in the industry in terms of diameter to thickness ratio. Its talc flakes exhibit a more regular and uniform sheet-like structure, with certain gaps and dispersion maintained between the scales. This makes the talc powder of Liaoning Xinda Talc Group Co., Ltd. have better reinforcement effect and dispersibility in plastics.

5、 Application effect of high aspect ratio talc powder in plastics

The application of 3000 mesh talc powder developed by Liaoning Xinda Talc Group in polypropylene plastics has achieved significant results. The following are specific application effects and market feedback:

5.1 Improve mechanical performance

Due to the more regular and uniform sheet-like structure of talc powder with high aspect ratio, it can better bond with polypropylene matrix. When subjected to external forces, talc sheets can more effectively transmit and disperse stress, thereby improving the mechanical properties of plastic products. The experimental results showed that after adding 3000 mesh talc powder from Liaoning Xinda Talc Group Co., Ltd., the tensile strength, bending strength, and impact strength of plastic products were significantly improved.

5.2 Improving heat resistance performance

Talc powder, as an inorganic filler, has high thermal stability. Adding it to polypropylene plastic can effectively improve the heat resistance of plastic products. Especially in high-temperature environments, talc powder with a high aspect ratio can absorb and uniformly conduct heat, thereby slowing down the thermal decomposition and degradation rate of the plastic matrix. The experimental results show that the addition of 3000 mesh talc powder from Liaoning Xinda Talc Group Co., Ltd. significantly improves the thermal deformation temperature and thermal stability of plastic products.

5.3 Cost Reduction

Talc powder, as a relatively inexpensive inorganic filler, can effectively reduce the cost of plastic products. By adding talc powder with a high aspect ratio, the amount of plastic matrix used can be reduced while ensuring the performance of plastic products. This not only reduces raw material costs, but also reduces energy consumption and waste emissions during the production process. Therefore, the 3000 mesh talc powder of Liaoning Xinda Talc Group Co., Ltd. has been widely used in plastic products and has received unanimous praise from customers.

6、 Conclusion

This article explores the application and advantages of high aspect ratio talc powder in plastics. Introduce the sheet-like structure and bonding method of talc powder, and analyze the technical difficulties in the production process. Then, based on the research and development achievements of Liaoning Xinda Talc Group's R&D department, the significant effect of its 3000 mesh talc powder in protecting large scales was introduced, and the superior diameter to thickness ratio of its talc powder was demonstrated through comparative pictures. Finally, the practical application effects and market feedback of high aspect ratio talc powder in plastics were summarized.

The experimental results show that the 3000 mesh talc powder of Liaoning Xinda Talc Group Co., Ltd. has excellent reinforcement effect, heat resistance, and cost reduction effect in plastics. Therefore, talc powder with high aspect ratio has broad application prospects and development potential in the plastic industry. In the future, we will continue to conduct in-depth research and explore new technologies and methods for the application of talc powder in plastics, making greater contributions to promoting the development of China's plastic industry.