A Raymond machine and a simple powder processing workshop - this is what Liaoning Xinda's talc business started in 1995. With a passion for the talc industry and a simple belief, Xindan has taken the first step towards exploration and development from here.

From 1995 to 2025, after thirty years of unremitting struggle, Xinda has risen proudly today, transforming from a single powder processing point to a comprehensive industrial group integrating talc mining, sorting, research and development, deep processing, and sales.

1、 Strong industrial layout, building a foundation for development

1 large mine

Xinda Talc Group has unique resource advantages, with one large mine and two medium-sized mines under its jurisdiction

2 medium-sized mines

The total area of the mining area is 1.7 million square meters, with a total reserve of up to 12 million tons. According to the current mining speed, it can be sustainably mined for 60 years, providing a solid resource guarantee for the long-term development of the group.

These mines are located on the main ore veins of the Liaonan talc deposit, producing world-class high-quality powder and white talc raw materials with excellent whiteness, purity, asbestos free and heavy metal free characteristics, making them ideal raw materials for producing high-quality talc products.

2、 Advanced production technology, creating excellent quality

The group also has three modern factories, Xinda Powder, Xinfuji Masterbatch, and Xinzhanpengda Hollow Plate, as well as a talc research and development center established by the China Non Metallic Mineral Products Association

Powder factory

30 years of professional accumulation, with an annual production capacity of 300000 tons. Equipped with 6 vertical mills, 12 air flow mills, including 4 double graded wheel air flow mills and 2 imported air flow mills, it can produce 400-12500 mesh sliding stone powder, with high-end powder accounting for 15% of the country's total.

Masterbatch factory

Established in 2007, with an annual production capacity of over 80000 tons and more than 20 high-end products to choose from. Producing high filling masterbatch products with advanced production technology, dust-free and high-performance, widely used in modified plastics for automobiles, household appliances and other fields.

Hollow board factory

3 advanced production lines, focusing on the research, development, production, and sales of various types of plastic hollow boards, corrugated boards, hollow board turnover boxes, transportation packaging boxes, etc., providing the market with a rich selection of products.

The group has a total of 16 airflow grinding production lines, 6 vertical grinding production lines, 36 digital production lines, 14 internal mixer production lines, and so on. Simultaneously possessing over 30 authoritative patent certifications, more than 50 corporate honors, and 16 national system certifications.

3、 Rich in creative spirit

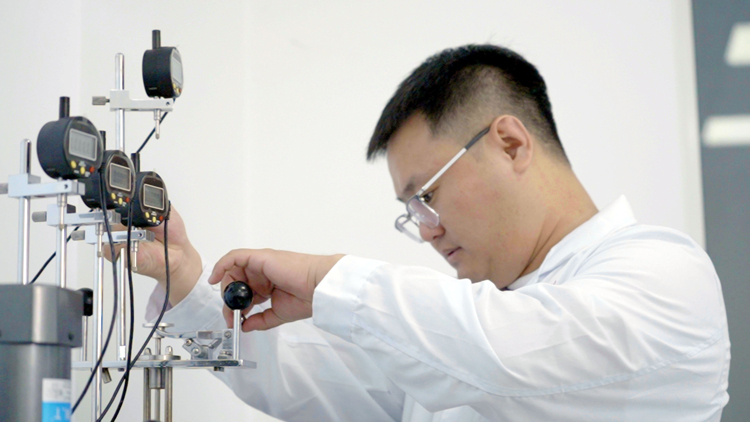

The group boasts a national-level talc technology research and development center established with the support of the China Non-Metallic Mining Industry Association. The center spans an area of 1,300 square meters and comprises one innovation studio, two expert studios, three processing laboratories, and four testing laboratories

In the future, Liaoning Xinda Talc Group will continue to adhere to the concept of innovative development, continuously optimize the industrial structure, improve product quality and technological level, strengthen cooperation and communication with domestic and foreign customers, and contribute more wisdom and strength to promote the development of the talc industry. Looking forward to working together with you to create a better future!