All along, Xinda Talc Group has deeply rooted the concept of environmental protection in the core of its corporate development. Its factories actively explore the journey of green development, practice their environmental mission with practical actions, and contribute to the sustainable development of this blue planet. Our group's factories are steadfast practitioners in this green wave, deeply cultivating their respective fields and integrating environmental protection concepts into every aspect of production and operation, paving the way for unique green development paths.

As an important participant in the resource extraction industry, the group's mines are well aware of the importance of green development for the earth's ecology and their own sustainable development, and are firmly committed to taking big strides towards the direction of green mines. The group's mines will invest a large amount of resources into the comprehensive ecological management of the mining area. A closed warehouse of 7000 square meters has been erected, effectively reducing the impact of material stacking on the environment; The hardening of over 9000 square meters of land and 700 meters of mining roads has not only improved the traffic conditions in the mining area, but also reduced dust pollution; The construction of a 350 meter long enclosed corridor has further optimized environmental protection measures during material transportation; More than 20 acres of land have been greened and reclaimed, and the once barren land is now lush with greenery, with a significant increase in vegetation coverage and a gradual restoration of ecological balance. The mine has also established development goals of "safety, environmental protection, health, efficiency, full coverage of mechanical automation, and comprehensive utilization of resources", drawing a clear blueprint for future green development. With outstanding achievements in the field of environmental protection, the group's mines successfully obtained the green mining qualification in Liaoning Province in November 2022.

|  |

Xinda Powder Factory also integrates environmental protection concepts throughout the entire production process. The factory is equipped with advanced production equipment, including 2 German imported flake air flow mills, 2 domestically advanced dual stage wheel air flow mills, 2 screening machines, and 6 vertical mills. The production line adopts fully enclosed pipe chain conveying technology, effectively avoiding external pollution and ensuring the purity of products from the source. The factory has also introduced a fully automated packaging production line, which realizes a series of automated operations such as bagging, measuring, counting, dust removal, coding, and high-level stacking of product packaging. The raw material feeding process adopts an automatic feeding system to accurately control the ratio and mixing process of talc raw materials, ensuring that the raw material ratio is scientific, reliable, and accurate, greatly reducing the fluctuation of product indicators, and making the technical indicators of product whiteness, color, etc. more stable, which not only meets environmental protection requirements but also meets customers' demand for high-quality products.

|  |

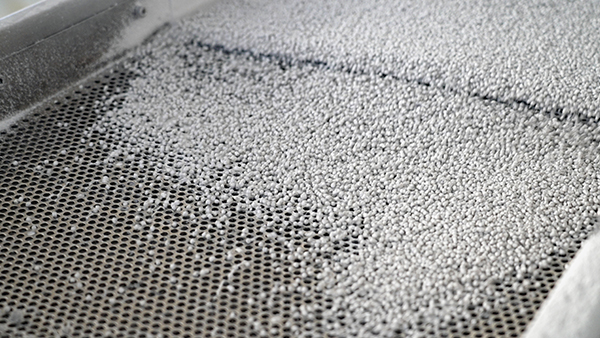

The masterbatch factory closely follows the trend of environmental protection development and, with the strong support of the group, has undergone a comprehensive upgrade and transformation. The group has invested 60 million yuan to enhance the intelligence of masterbatch processing, centralized storage of raw materials, and sealing of powder transportation. After unremitting efforts, the current masterbatch factory has successfully transformed into a green and environmentally friendly masterbatch deep processing production base. The various indicators of the products produced by it meet the national environmental protection requirements. With advanced technology and stable quality, the overall production capacity of the factory has risen to the forefront in China. Xinfuji masterbatch factory always adheres to strict management mode and advanced technological means, continuously optimizes industrial structure, improves product quality, and only provides better products and services to our customers. In the future, the factory is full of expectations to work hand in hand with more domestic and foreign customers to achieve win-win cooperation on the road of green development.

|  |

Hollow board factories contribute to environmental protection with their unique product advantages. Compared with ordinary paper boards, plastic hollow board products have many significant advantages. It has excellent waterproof, moisture-proof, corrosion-resistant, and insect resistant properties, with high load-bearing strength and tear and tensile strength far exceeding ordinary cardboard. Its reusability is 4-10 times that of corrugated cardboard. In addition, the hollow board comes in a variety of colors, which can be added according to customers' personalized needs. This not only provides customers with more diversified choices, but also effectively reduces resource waste and negative impact on the environment due to its good durability and recyclability, making it a high-quality choice for environmentally friendly packaging materials.

|  |

Under the guidance of World Earth Day, each factory under the group will continue to take environmental protection as the foundation of development, constantly explore and innovate green production technologies and management models, steadily move forward on the path of green development, and contribute more wisdom and strength to safeguarding our home planet and promoting global sustainable development.