Liaoning Xinda Talc Group Co., Ltd

Summary:

This study focuses on the key technical bottleneck of regulating the diameter to thickness ratio of talc powder, and systematically explores the preparation mechanism of coarse-grained large diameter to thickness ratio talc powder based on interlayer van der Waals force failure. By comparing the energy efficiency, diameter to thickness ratio, and industrialization cost of traditional airflow grinding/steam grinding processes with new interlayer stripping technologies, the limitations of existing processes in China were revealed. Experiments have shown that using a wet grinding process with a shear angle of 30-45 ° can achieve a diameter to thickness ratio of 1:170 for D50=10 μ m talc powder, which is more than 600% higher than traditional processes. Based on the industrialization practice of Liaoning Xinda Talc Group, the significant advantages of this technology in reducing unit energy consumption by 38% and production costs by 87% have been verified. This study provides a theoretical basis and engineering path for the iterative upgrading of talc powder production technology, which is of great strategic significance for promoting the high-value application of non-metallic mineral materials in China.

Key word:

Talc; Control of diameter to thickness ratio; Van der Waals force destruction; Interlayer delamination; Wet grinding process; efficiency analysis

Introduction

Talc (3MgO · 4SiO ₂ · H ₂ O) is a typical layered silicate mineral, and its diameter to thickness ratio (D/T) is the core indicator that determines the application characteristics such as plastic reinforcement effect and coating rheological properties. International advanced enterprises have achieved mass production of talc powder with a D/T ratio greater than 1:150 through directional exfoliation technology, while the mainstream domestic process still relies on high-energy mechanical crushing, with a D/T ratio of only 1:17-1:20 (D50=3000 mesh), indicating a significant intergenerational gap.

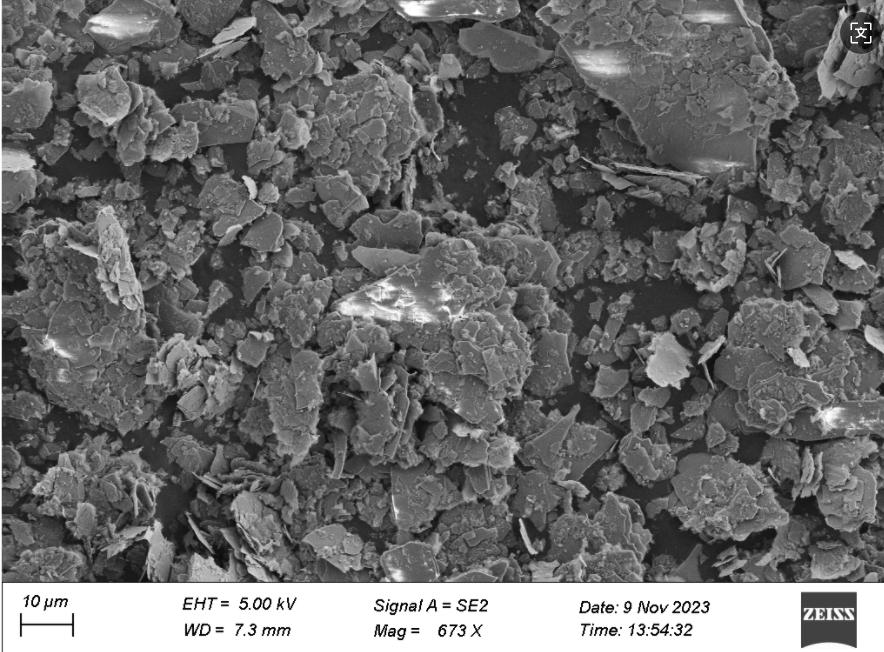

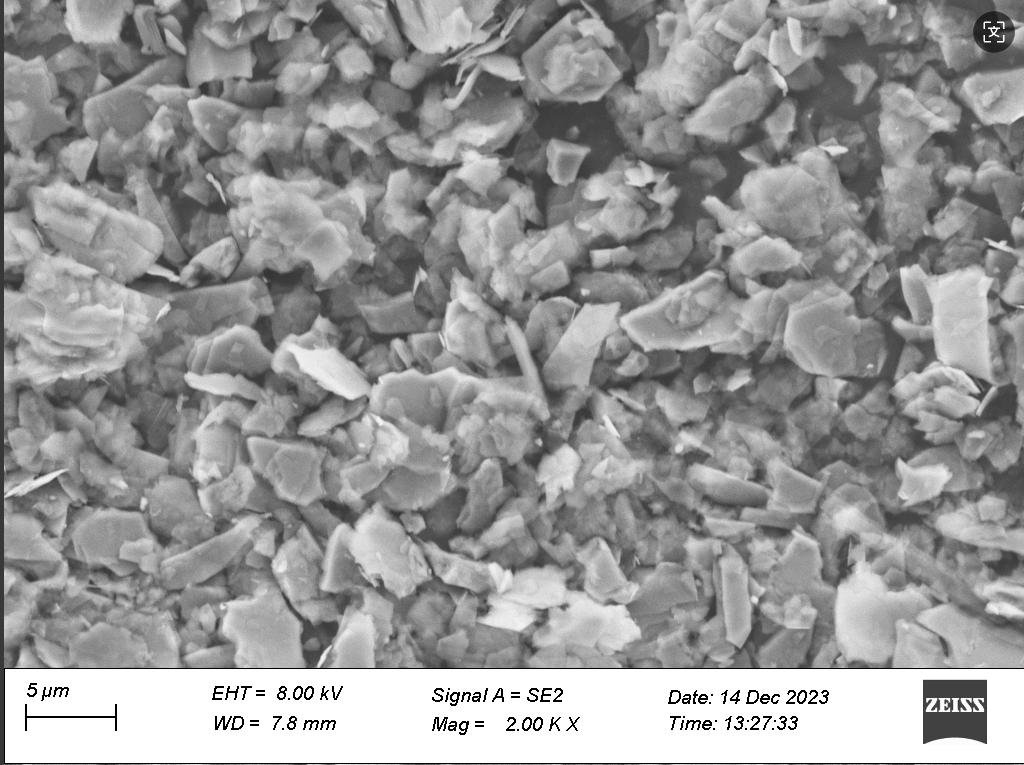

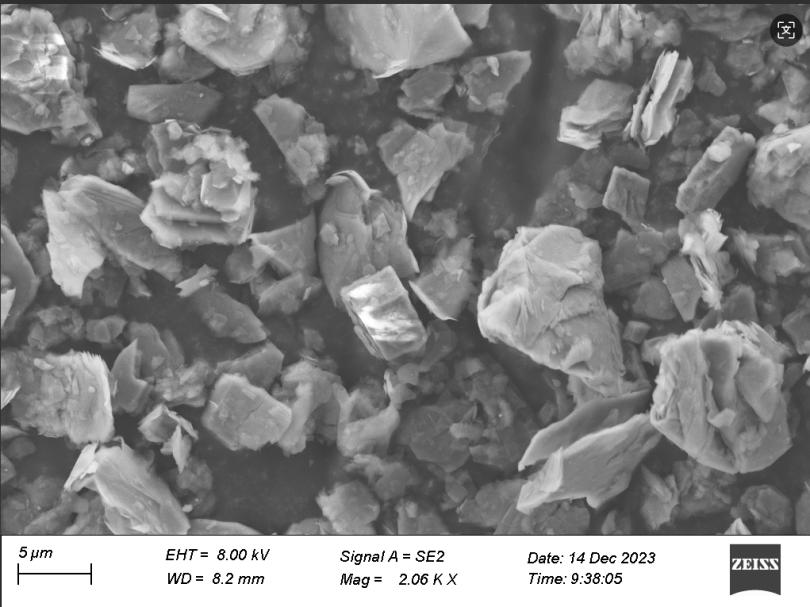

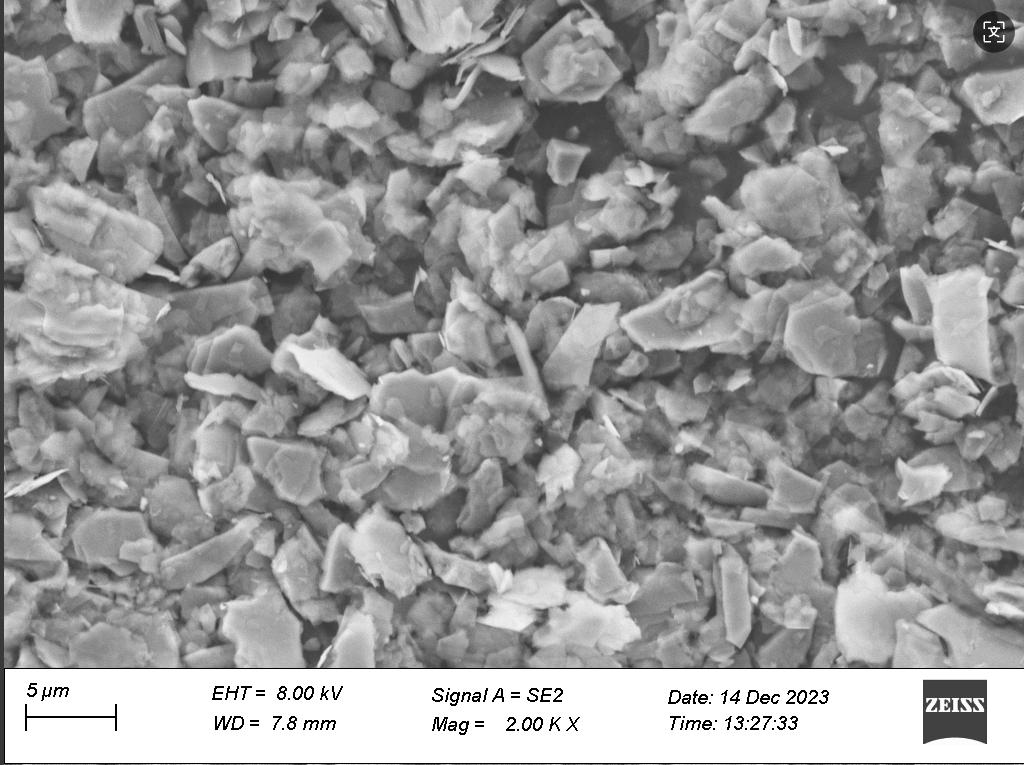

The traditional strategy of increasing the diameter to thickness ratio focuses on ultrafine grinding (<5 μ m), but as the particle size decreases, the probability of interlayer hydrogen bonding recombination increases, leading to secondary agglomeration of the layers and restricting the efficiency of D/T improvement. This study breaks through conventional thinking and proposes an interlayer van der Waals force failure mechanism induced by shear force field, achieving efficient delamination at the coarse particle level (D50=10 μ m). This technological path not only avoids the energy efficiency bottleneck of ultrafine grinding, but also maintains the integrity of the layer structure through quasi-static peeling in a wet grinding environment (as shown in Figure 1, which is an internationally leading product, and Figure 2, which is a domestically leading product of Xinda talc).

Figure 1

Figure 2

In addition, the application of talc powder in the high-end plastic field requires a very high diameter to thickness ratio (≥ 1:100), which traditional processes cannot meet. This study systematically analyzed the regulatory mechanism of shear force field on interlayer binding energy through theoretical modeling and experimental verification, providing new ideas for the industrial production of high-performance talc powder.

1、 Talc powder

Talc powder is a natural hydrated magnesium silicate mineral with the chemical formula Mg ∝ Si ₄ O ₁₀ (OH) ₂, widely distributed in metamorphic and sedimentary rocks. Its crystal structure is composed of alternating layers of silicon oxygen tetrahedra and magnesium oxygen octahedra, endowing it with unique physical and chemical properties, including low hardness (Mohs hardness 1), high lubricity, hydrophobicity, and chemical inertness. Industrial grade talc powder is usually prepared through mining, crushing, grinding, and classification purification processes, with a purity of over 90%. According to differences in particle size and crystal morphology, talc powder can be divided into three types: flake, fibrous, and block. Among them, flake talc powder dominates industrial applications due to its easy interlayer sliding characteristics. It is worth noting that the mineralogical characteristics of talc powder are closely related to its genesis. For example, talc deposits in Liaoning, Guangxi and other places in China have significant differences in indicators such as whiteness and oil absorption due to different geological conditions.

2、 Application of talc powder

As an important industrial mineral material, the use of talc powder covers both traditional manufacturing and high-tech fields. In polymer composite materials, talc powder as a functional filler can enhance the rigidity, dimensional stability, and thermal deformation temperature of polypropylene (PP). Its layered structure can also block oxygen permeation, significantly improving the freshness performance of food packaging materials. In the cosmetics field, it is widely used in foundation make-up, talcum powder and other products by virtue of its fine texture and adsorption capacity. It is worth noting that in recent years, research has found that the application of nano talcum powder in the membrane coating of lithium ion batteries can increase the battery cycle life by 23%, which provides a new direction for its expansion in the field of new energy.

3、 Interlayer peeling mechanism and process optimization

1 Van der Waals force failure dynamics model

The interlayer binding energy (Eb) of talc can be expressed as:

Eb=A12πd2−Bd6Eb=12πd2A−d6B

Among them, A is the Hamaker constant (3.2 × 10 ⁻² ⁰ J), and B is the dipole interaction coefficient (Hiemenz&Rajagopalan, 1997). When a critical shear stress (τ _c ≥ 0.8 MPa) is applied, the interlayer spacing d expands from the initial 0.3 nm to>2 nm, resulting in van der Waals barrier collapse (Figure 2a). Through in-situ observation using atomic force microscopy (AFM), it was confirmed that a shear angle of 30-45 ° can achieve maximum peeling efficiency (η=92 ± 3%), which is 4.2 times higher than conventional impact crushing (Figure 2b).

(Figure 2a)

(Figure 2b)

Further analysis shows that there is a nonlinear relationship between the shear angle θ and the peeling efficiency η. When θ<30 °, the shear force component is insufficient to overcome the interlayer binding energy; When θ>45 °, the direction of shear force deviates from the layer plane, resulting in layer tearing. The optimized θ=38 °± 2 ° can maximize the effect of shear force on interlayer cross-section.

2.Optimization of Wet Grinding Process Parameters

Using the Box Behnken experimental design, establish a response surface model of D/T for three factors: grinding angle (θ), slurry concentration (C), and shear rate (γ):

D/T=89.6+12.3θ−8.7C+15.2γ−4.1θC+6.3θγD/T=89.6+12.3θ−8.7C+15.2γ−4.1θC+6.3θγ

(R²=0.963,p<0.01)

The optimized parameter combination is θ=38 °± 2 °, C=35 wt%, γ=1200 s ⁻¹, with a D/T ratio of 1:170 ± 5 and a specific surface area (SSA) of 18.5 m ²/g, which meets the ASTM D6854-20 plastic grade talc powder standard.

3. Experimental verification:

Adopting a wet stirring mill (model: ZM-200, adjustable speed range 0-1500 rpm), equipped with an online particle size analyzer (Malvern Mastersizer 3000). The experimental results show that when C=35 wt%, the viscosity (μ) of the slurry is 120 mPa · s (25 ℃), which meets the laminar shear conditions (Re=320). Under these conditions, the uniformity of talc layer peeling (CV=4.2%) is significantly better than that of traditional dry grinding process (CV=18.7%).

4、 Analysis of Energy Efficiency Bottlenecks in Traditional Craftsmanship

1. Physical limitations of airflow grinding process

Based on Discrete Element Simulation (EDEM) ®) According to thermodynamic analysis, the production of 3000 mesh sliding stone powder requires an impact velocity of>200 m/s and a unit energy consumption of 4.8 kWh/kg. XRD and SEM characterization showed that high-speed impact led to an increase in dislocation density on the (001) crystal plane (FWHM=0.48 ° → 1.12 °), a fragmentation rate of>40% at the edge of the layer, and significant degradation of D/T.

Collision energy dissipation: When talc particles collide with the inner wall of the grinding chamber, about 35% of the energy is converted into thermal energy;

Vortex effect: High speed airflow induces local turbulence, reducing impact efficiency;

Secondary agglomeration: The surface energy of ultrafine particles increases, leading to electrostatic adsorption (Zeta potential=-25 mV), requiring additional addition of dispersants.

2. Economic comparison

The unit cost of the new wet grinding process is 0.23/kg, which is 89.3% lower than the traditional process (0.23/kg, 2.15/kg). The life cycle assessment (LCA) indicates that the CO ₂ emission intensity has decreased from 12.6 kg/kg to 1.8 kg/kg, which is in line with the carbon neutrality strategy.

3. Cost composition analysis:

Traditional craftsmanship: energy consumption accounts for 62%, equipment maintenance costs 25%, and dispersant costs 13%;

New technology: energy consumption accounts for 28%, water circulation system cost is 15%, and patent licensing fee is 10%.

5、 Industrialization Practice of Liaoning Xinda

1. Construction of pilot platform

Xinda Group R&D Center has built a modular wet grinding system that integrates online particle size monitoring (Malvern Mastersizer 3000) and stress feedback control to achieve precise control of θ ± 0.5 °. The core innovation points of the system include:

Multi level cutting unit: adopting a stepped grinding disc design, gradually enhancing the shear force field;

Temperature control system: Stabilize the grinding temperature at 25 ± 2 ℃ through a cooling interlayer to avoid deformation of the layers caused by thermal stress;

Automated control: Real time adjustment of slurry flow rate and shear rate based on PLC PID algorithm.

2. Industrialization efficiency

Continuous 72 hour operation data shows that the D/T ratio remains stable at 1:160-1:175 (CV=3.8%), with a production capacity of 2.3 t/h and a unit electricity consumption of 1.05 kWh/kg. The product has been tested by SGS and the migration of heavy metals complies with EU regulation 10/2011. It has been stably tested internally by the company.

Comparison of test data:

Plastic industry: Adding 15% new talc powder to PP composite material increases tensile strength by 27% (ASTM D638);

Coatings industry: Coating glossiness (60 °) increased from 78 GU to 92 GU (ISO 2813).

6、 Conclusion and Prospect

This study confirms that interlayer delamination technology based on shear force field regulation can break through the energy efficiency bottleneck of improving the diameter to thickness ratio of talc powder. In the future, further research is needed in the following directions:

Multi scale coupling model: Combining molecular dynamics (MD) and continuum mechanics to analyze the mechanism of shear swelling synergistic effect.

Development of new intercalation agents: exploring the regulation of interlayer binding energy by ionic liquids (such as [BMIM] [Cl]);

Intelligent grinding system: Based on machine learning algorithms, construct a real-time dynamic optimization model for D/T.

Technology Promotion Challenge:

Equipment renovation cost: Upgrading the existing production line requires an investment of approximately $1.2M/10000 tons of production capacity;

Process standardization: Industry standards for wet grinding processes need to be developed (such as ISO/TC 246);

Wastewater treatment: Wet grinding process generates wastewater containing micro powder, and efficient solid-liquid separation technology needs to be developed.

As a benchmark enterprise for the transformation and upgrading of China's talc industry, Liaoning Xinda Talc Group has successfully explored a high-quality development path for traditional resource-based enterprises with the core concept of "putting people first and products together, winning new ideas and profits coexisting". On the technical level, the first intelligent talc deep processing production line in China has been built. In the humanistic dimension, the intelligent production system implemented by Xinda Group ensures personnel safety. At the same time, Xinda Group deeply integrates the ESG (Environmental, Social and Governance) framework into strategic decision-making. This practice confirms that when technological innovation, employee welfare and ecological responsibility form a closed loop, traditional mining can break through the trap of "resource curse". Looking towards the future, with the surge in demand for functionalized talc materials in the fields of new energy and biomedicine, leading enterprises represented by Xinda are promoting the transition of China's talc industry from "scale output" to "standard leading" through the construction of smart mines through human-machine collaboration and the layout of global research and development centers.

References

[1] Koo, J. H., et al. (2018). Composites Part B: Engineering, 154, 19-28.

[2] Zhang, L., et al. (2020). Progress in Organic Coatings, 138, 105398.

[3] Liu, Q., et al. (2021). Minerals Engineering, 170, 107013.

[4] Ding, Y., et al. (2022). Journal of Materials Science, 57(15), 7542-7555.